With the development of electronic devices toward to diversification of varieties ,functionality and Product minimization, Printed Circuit Board manufacturing industry faces the challenge of more sophisticated equipment and more advanced technologies.

Universe Group ,as professional wet pcb process equipment manufacturer, is facing current challenges and gradually introducing industy 4.0 intelligent production mode. It reserches and developes and make independently the vertical continuous plating line (VCP). Since 2011, just a few short years, VCP sales volume has exceeded 121 lines. It is widely used for pcb manufacturing process such as: panel plating, graphics plating, filling holes or half-filling holes plating, soft board plating and so on.

It is reported, the design concept of the universe group VCP line is updated on the basis of traditional plating line .Compared with traditional plating line, it has more advantages as below :

Device of loading / unloading material: the universe group VCP line adopts automatic design of loading and unloading material. The shortest cycle is only 8 seconds.

While traditional plating line can only load and unload the material by manual, which needs more operators, and the labor intensity is high, the staff turnover is fast, which is easy to cause Labour shortages.

While traditional plating line can only load and unload the material by manual, which needs more operators, and the labor intensity is high, the staff turnover is fast, which is easy to cause Labour shortages.

Transmission structure: the universe group VCP line adopts transmission way of combination chain type with movable cathode pylons. Pylons drive more smoothly and connectibity is better. it has the advantage of less impact and low noise, etc;

While traditional plating line, impact and noise of bumble motor making serious noise pollution.

The device of adding copper ball:the VCP line can add copper ball during the PCB production.You can add the copper ball at any time without stopping the machine.This operation is very convenient and the copper ball will not fall into the copper groove .

While traditional plating line needs to stop the machine when adding copper ball, which is extremely unconvenient, and copper ball is easy to fall into the groove. Its efficiency is low and affect the production capacity.

Production environment: in the same capacity, compared with traditional plating ,the contact area between liquid and air of VCP line is smaller,which is only a third of traditional plating line.Using the lateral jet produces less waste gas,so the required pumping air volume is small,and energy consumption is slow.The top extraction design of sealed equipment can greatly reduce gas leaks, which makes work environment safe and comfortable;

While traditional plating line is open.It is difficult for traditional plating line to achieve the effect of VCP in sealing.Because the quantity of copper plating tank is big, and the surface area of exposed liquid in air is much, and pylon has frequent movement which produces a large amonut of waste gas. So the whole workshop has harmful gas,which has serious impact on employee health. The pcb manufacturer need to configure high-power convulsions system to make the environment improve slightly, and energy consumption is high.The conservative estimated enerhy consumption is more than two times than VCP line .

Process control: the copper tank of the universe VCP line is all connected, and uniform circular, whose tank is equivalent to one copper groove.In process control, only liquid in one copper slot or several copper slot is needed,which is simple and easy to analysis;

And traditional plating line, the number of copper slot is much.The copper tank works alone and does not connect together.In process control,the liquid in every copper tank is needed to analysis,which makes process tedious and big workload.

Body material: the body of VCP line is made of flame retardant PVC material of V0 class.When in the fire,it most becomes black ,but not burn,which can effectively prevent the fire.The so-called prevention is like that;

While traditional plating line is generally made of ordinary PP material.PP material is not only easy to burn but more help burn. Throughout the fire in PCB factory, it is mostly caused by plating workshop,while the flammable PP material is one of the main culprit causing the fire;

Floor space:the structrure of the VCP line is compact, and the floor space is small ;The universe group has a total four kinds of VCP equipment:

double up-down VCP line(called a DVCP), single up-down VCP line, circular transfer VCP line, one-piece transmission ring VCP line.They can satisfy users of different site conditions,and it is very flexible and convenient;

double up-down VCP line(called a DVCP), single up-down VCP line, circular transfer VCP line, one-piece transmission ring VCP line.They can satisfy users of different site conditions,and it is very flexible and convenient;

While traditional plating line, the floor area is larger, and requirements for plant height is high, which is at least 4 ~ 5 meters;Under the same capacity condition,space required by VCP line is only 50% of the traditional plating line, which greatly save space.

Maintenance: the structure of the VCP line is simple, and adopt humanized design with fool proof, and quick release, and color letter management.It is extremely convenient and high efficiency, and it is also easy to achieve 7S standard.

While traditional plating line ,its copper plating tank span is big, and it is easy to cause accident. It often exists environmental problems, and maintenance person need to be down to clean the copper tank, extremely unconvenient. The fixture needs frequent maintenance and repair, and the cost is high.

Flexiable PCB production: the VCP line can directly produce the flex PCB board with 0.036 mm thickness or above without the fixed framework; Traditional plating line need the frame during producting any kinds of flex board.

Through-hole ability: the VCP line uses the supercharged nozzle to spray up closely, to strengthen liquid penetration ability, which can meet the demand of HDI PCB production;

While traditional plating line makes the potion into the hole only by soaking and swing. Its strength is small, and penetration ability is limited, so it can only meet the demand of ordinary plate production.

While traditional plating line makes the potion into the hole only by soaking and swing. Its strength is small, and penetration ability is limited, so it can only meet the demand of ordinary plate production.

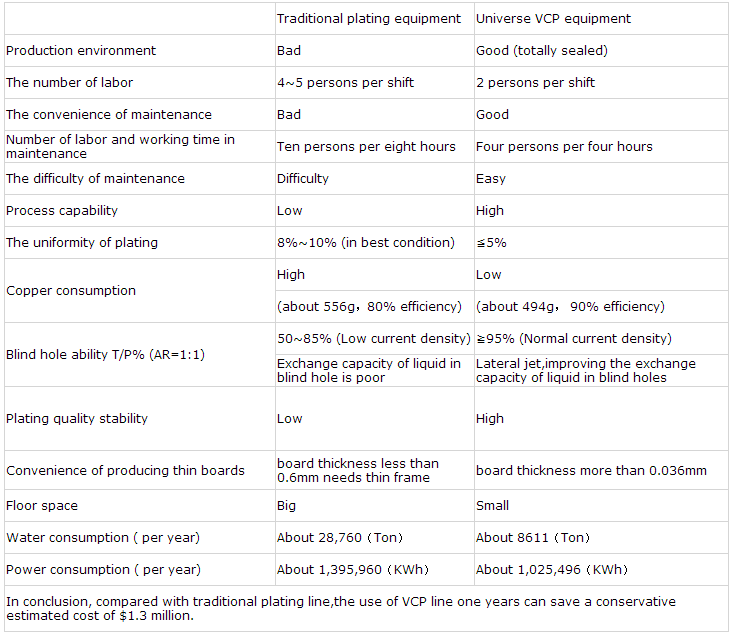

Conclusion: the advantages and disadvantages between VCP line and traditional plating line, as follows:

Due to the limitations of structure and technology, traditional plating line has gradually lost its competitive advantage.In addition to producing a small part of the high depth of the products,the more cost-effective VCP line will replace the traditional plating line.Universe Group VCP line is a good example of industy.we believe,under the impetus of outstanding enterprise as the universe group, the development or PCB manufacturing industry toward to the sustainable and healthy direction of low consumption, low pollution, high quality, high efficient.

Source from http://www.ifastpcb.com/blog/vertical-continuous-platingvcp-line-completely-defeat-traditional-plating-line-boost-healthy-development-pcb-manufacturing-2/

No comments:

Post a Comment